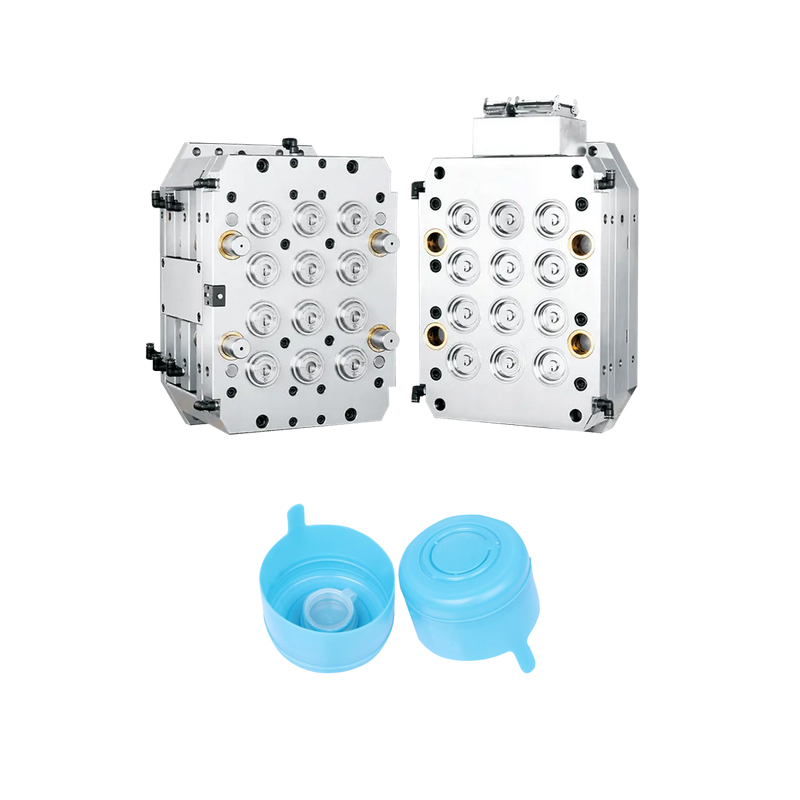

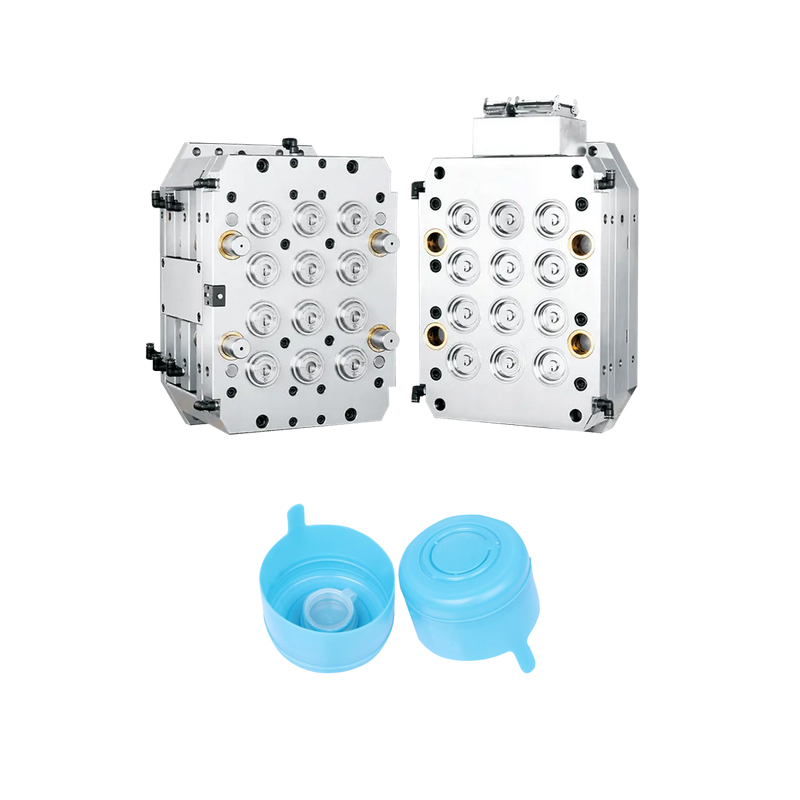

A plastic bottle cap mould is a type of mould used in the manufacturing process of plastic bottle caps. These moulds are made from high-quality materials and are designed to produce precise and consistent bottle caps at a high volume. They play an essential role in the manufacturing process of plastic bottles, ensuring that the caps fit securely and reliably on the bottles.

One of the main benefits of using a plastic bottle cap mould is the precision and consistency that can be achieved in the manufacturing process. These moulds are designed with great attention to detail, ensuring that each cap is of a consistent size and shape. This is essential for ensuring that the caps fit properly on the bottles and can be easily opened and closed.

Another benefit of using a plastic bottle cap mould is the speed and efficiency of the manufacturing process. Once the mould is set up and ready to go, it can produce large quantities of identical caps in a relatively short amount of time. This makes it an ideal choice for high-volume production applications.

In addition to their precision and efficiency, plastic bottle cap moulds are also highly customizable. The design of the mould can be adjusted to create caps in a variety of sizes and shapes, making it easy to create caps that meet the specific needs of a particular application. This is particularly important in industries such as food and beverage manufacturing, where different types of bottles may require different types of caps.

Another benefit of plastic bottle cap moulds is their durability. These moulds are typically made from high-quality materials that are resistant to wear and tear, ensuring that they can be used for many years without needing to be replaced. This is important for manufacturers who need to produce large quantities of bottle caps on a regular basis, as it helps to reduce downtime and maintenance costs.

One potential downside of plastic bottle cap moulds is their initial cost. These moulds can be expensive to purchase and set up, particularly for smaller manufacturers or those who only require a small number of caps. However, for those who require large quantities of caps, the cost of the mould may be offset by the savings achieved through high-volume production.

In conclusion, plastic bottle cap moulds are an essential tool for manufacturers who need to produce large quantities of bottle caps on a regular basis. They offer precision, speed, and efficiency in the manufacturing process, while also allowing for customization and durability. While the initial cost of the mould may be high, the benefits it provides can make it a worthwhile investment for manufacturers in a variety of industries.