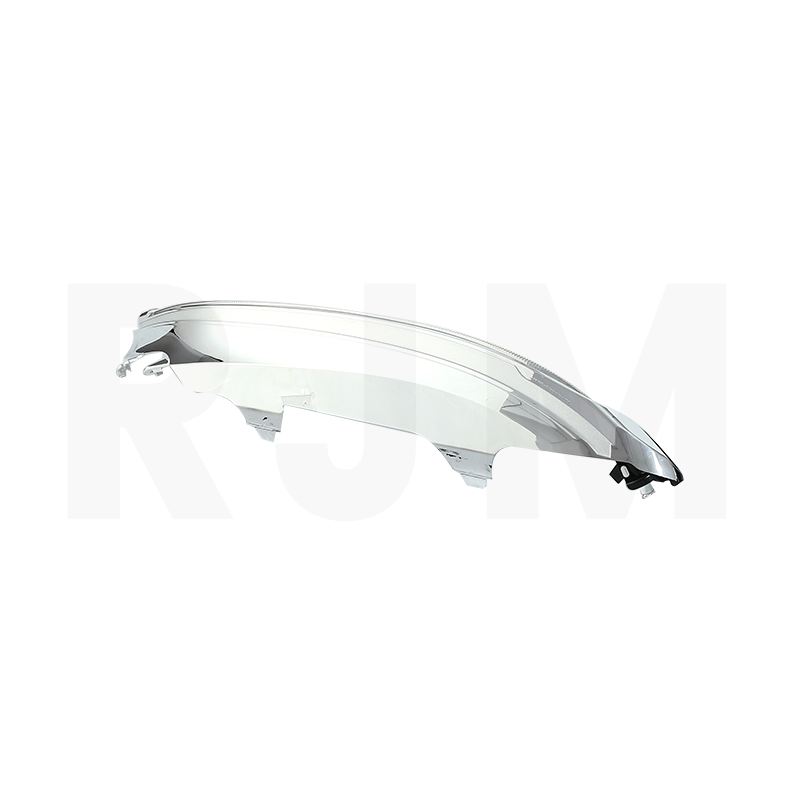

If you need to make crates for shipping purposes, you can make use of a

plastic crate mould. These moulds are widely used to create crates of all sizes. They are also a great help in ensuring that a heavy item is properly loaded. These moulds are manufactured by specialized plastic injection mould manufacturers. These moulds are made to withstand pressure.

There are many factors that you need to consider when choosing a mould. Firstly, the material you are using should be able to withstand the crates' weight and size. For example, if you are using plastic, you should choose a plastic with a low MFI, such as 4 or 6. On the other hand, if you are using metal, you should choose a mould with a high RPM screw and a high base steel.

The cost of a mould will depend on several factors, such as the number of moulds, the complexity of the design, and the material used. There are a variety of mould manufacturers that offer quality products at affordable prices. You can also ask for a free quote before making a final decision.

Apart from the material, you should also consider the quality of the mould steel. A mould with a high HRC is more durable than one made with lower-grade steel. You should also check if the mould steel is heat treated. Common P20 mould steel has a hardness of HRC30, but heat treatment can make it harder, thus improving the product quality and mould life. The type of heat treatment will also affect the price of the mould.

A mould manufacturer with extensive experience in plastic injection moulds will be able to meet your needs for quality milk crates. The mould should be accurate, smooth, and durable. It should also have a foldable lid to keep a product covered. Moreover, it should also be able to produce the desired plastic products.

Hot runner moulds are cheaper than their cold counterparts. However, they are generally used for high volumes of 500 000 parts. However, smaller quantities can also be produced using hot runner moulds. You can also use a hybrid hot runner and cold runner system to make larger components. The ejection cycle time is shorter and more consistent.

-

|

Mould material

|

45# 50# 718 2738 P20 H13 S136 etc

|

|

Cavity Number:

|

As per customer

|

|

Runner System:

|

Hot runner / Cold runner

|

|

Hot runner Brand:

|

Local brand or YUDO

|

|

Mould Design:

|

3D Model/2D drawing

|

|

Design Time:

|

Within 1 week

|

|

Mold Life:

|

0.5 to 1 million shots guarantee, depends on your needs

|

|

Delivery Time:

|

30 to 70 days as per design

|

English

English Español

Español

pmj01.png)

pmj04.png)