PET preform moulds are produced through a precision blow molding process. In this process, the preforms are blown into the desired shape and size. PET preforms are used for a variety of products and are customized for client requirements. These preforms can be used for mineral water, juices, liquors, carbonated beverages, soft drinks, and even consumer products such as cosmetics and oils.

The process of molding PET preforms requires careful planning and design to ensure the best results. It is important to choose the right steel, processes, and interface equipment. Proper cooling of the preforms is a critical element to achieving quality and reducing overall cycle time. Also, specially designed and processed water channels minimize the risk of jamming. In addition, a Pin-valve Hot Runner System reduces processing time, part wear, gate trim costs, and electricity consumption.

In addition, the preform mould must be economical to use while manufacturing PET preforms. A mould should utilize appropriate steel and processes to maximize production and minimize overall costs. A preform mould trial video is provided by mould to help customers choose the right mould for their production needs. mould also provides a full set of spare parts for your mould. The mold is a critical part of the process for producing a quality product.

The proper design of a plastics PET preform mould must be thoroughly understood by the engineer responsible for building it. This requires extensive knowledge of materials, processes, and the PET preform moulding process. The engineer should also have an understanding of the economics of production schedules and tooling. He should also be familiar with his own plant and have a comprehensive understanding of the process.

In addition to having high-quality preforms, it also produces low-profile mold assemblies and manifolds. These components are designed to reduce overall mold size and weight. Because of these features, Kortec's preform molds can be accommodated on smaller injection machines. They are also ideal for specialty applications, such as beer bottles and stadiums.

Choosing the right temperature for your PET preform mould is critical. The temperature of the water must be between 8 C (46 F) and 50 F. In hotter and humid climates, this can be very expensive. If your water temperature is too low, it may be wise to use a cooler.

If you use a chiller, be sure to add a minimal percentage of anti-freeze to keep your mold cool. Anti-freeze has a lower cooling capacity than water, and it is hard on the pumps. Moreover, you should keep the water flow balanced. For example, a mold with water in and out ports on the same side will cool the mould more efficiently, while one with different inlets and outlets will cause it to cool more slowly.

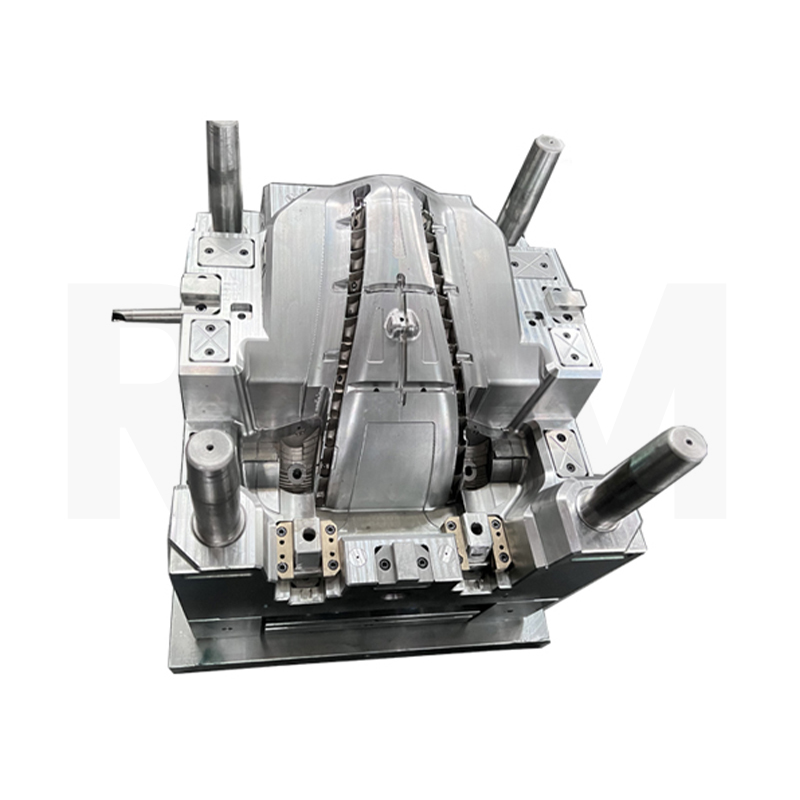

Custom pin valve gate PET preform mould

Custom pin valve gate PET preform mould

1. Preform Mould Core & Cavity material: S136 with vacuum hardening - HRC: 50 – 52

2. Cavity number: 24 cavities (can be customized according to your machine size)

3. Runner system: hot runner(pin valve gate)

4. Mould life: 1 million shots

5. Lead time: 25 - 35 days

-

|

Mould material

|

45# 50# 718 2738 P20 H13 S136 etc

|

|

Cavity Number:

|

As per customer

|

|

Runner System:

|

Hot runner / Cold runner

|

|

Hot runner Brand:

|

Local brand or YUDO

|

|

Mould Design:

|

3D Model/2D drawing

|

|

Design Time:

|

Within 1 week

|

|

Mold Life:

|

0.5 to 1 million shots guarantee, depends on your needs

|

|

Delivery Time:

|

30 to 70 days as per design

|

English

English Español

Español