An Auto Parts Mould is a crucial piece of equipment used in the production of automotive parts. These molds are specially designed to produce high-quality plastic parts. During this process, molten plastic is injected into the mold cavity and then hardens and solidifies. The finished part is then removed from the mold. This process is incredibly efficient, producing parts with complex shapes and a high degree of durability.

The quality of automotive parts depends on the accuracy of the molds. Injection molding involves filling specially made molds with liquid plastic that hardens into the final component. This technique scales easily for mass production. It can produce tens of thousands of parts per mold, while maintaining the same level of quality.

A good Auto Parts Mould manufacturer should have experience in the automotive industry. They should have their own injection moulding production facilities. This is essential because the final product must meet certain standards of consistency and quality. A professional mold manufacturer can also utilize a computer to make sure that the process is as accurate as possible.

An injection-molded part has a superior surface finish, which makes it an excellent choice for manufacturing automotive parts. Moreover, it is fast, meaning that a single part can be produced within a few minutes. Automotive parts made in this manner are generally defect-free. Additionally, plastic injection molding manufacturers offer a wide range of surface finishes for their products. Injection molding also allows for color modification, since the finished product is colored directly from the auto Parts Mould.

Plastic injection molding is the predominant method for producing automotive plastic parts. This technique is used in the production of many exterior automotive components, including bumpers and door handles. The durable plastic used in injection-molded parts makes it an excellent option for these components. Splash guards, for example, are a great example of the durability of plastic injection-molded parts.

Automotive Plastic Injection Mould manufacturers use various plastic polymers. Some of these materials are ABS and polypropylene, which are highly resistant to chemicals, water and UV light. Injection molding can produce all kinds of parts, including dashboards, car covers, and other parts for automotive manufacturing.

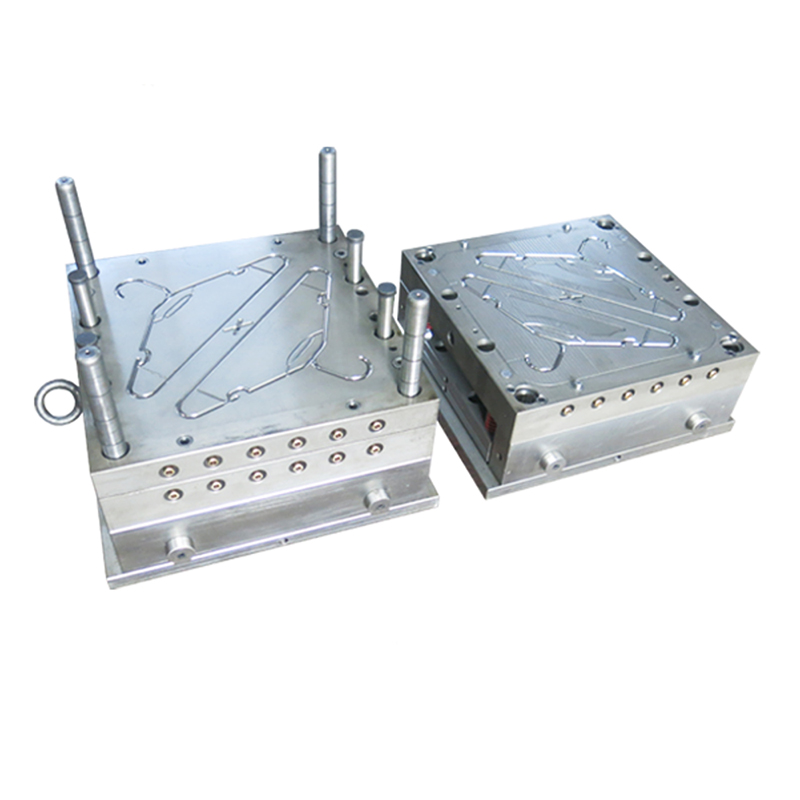

Injection molding is also used to manufacture multiple aesthetic exterior components of cars. A three-plate mold is a great choice for molding 100 or more parts. A three-plate mold is useful when the runner system and sprue parting plane are on different planes. This allows for ejection of the runner system and sprue.

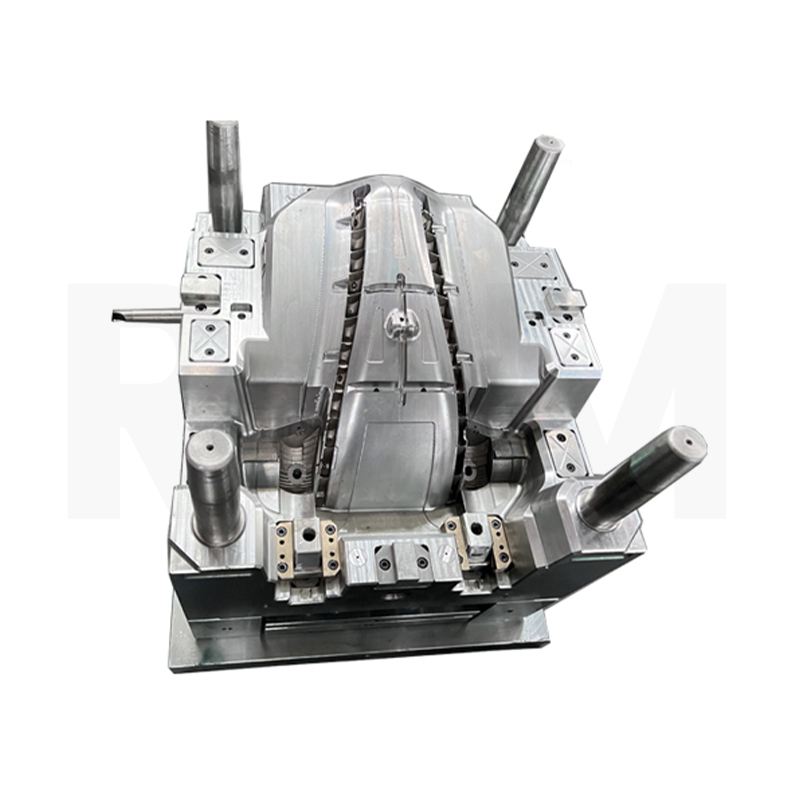

One color plastic auto lamp mould

1. Mould cavity number: 1 cavity2. Mould material: 2738 steel3. Runner system: Hot runner (one point)4. Delivery time: 40 - 65 daysRJ mould is a one-stop solution auto lamp mould factory. Send an inquiry now if you have any new auto lamp mould project!

-

|

Mould material

|

45# 50# 718 2738 P20 H13 S136 etc

|

|

Cavity Number:

|

As per customer

|

|

Runner System:

|

Hot runner / Cold runner

|

|

Hot runner Brand:

|

Local brand or YUDO

|

|

Mould Design:

|

3D Model/2D drawing

|

|

Design Time:

|

Within 1 week

|

|

Mold Life:

|

0.5 to 1 million shots guarantee, depends on your needs

|

|

Delivery Time:

|

30 to 70 days as per design

|

English

English Español

Español

pmj02.png)