A Bottle Cap Mould is an essential component of the manufacturing process of a bottle cap. Made from stainless steel, bottle cap moulds produce several caps at a time. The design of a mould goes beyond just the geometry of the bottle cap, as it must be durable and able to withstand thousands of pascals of pressure. It must also eject the parts without damaging or leaving imprints. In addition, it should be easy to clean, as bottle caps must be placed light to dark.

This innovative tool allows you to produce a variety of plastic bottle caps. Its four cavity design and selected metal grades enable it to produce a wide range of bottles, including 83mm jar caps. The four cavities in the design are designed to ensure a smooth surface, and the air-blowing function improves the cooling effect. This tool also reduces the overall thickness of the mould, thereby improving productivity. It is made of high-quality plastic and metal that is resistant to wear and tear.

A Bottle Cap Mould is the most essential part of the injection moulding process. A bottle cap mould's dimensions and weight are determined by its density and cooling time. As mould temperatures increase, the cap's dimensions and weight also decrease. Compared to demoulding, this process has a constant cooling efficiency and less distortion. So, before you invest in a Bottle Cap Mould, make sure you know exactly what you're getting.

A standard bottle cap mould should have a standard wad, which is the lining material between the bottle cap and the container. Standard wad sizes are 24mm, 28mm, and 38mm. The process of installing the lining material is fully automated using machine vision robotics. A full automated system ensures that the process will be done correctly. The machine should also be flexible and scalable to meet your production needs. In this way, it can be used for many different products.

While choosing a Bottle Cap Mould, make sure to check the manufacturer's experience and quality. Look at their reputation, customer reviews, and working history. The material used to produce the cap is an important factor, as it affects the performance of the product. It should also be made by a company that has access to adequate supplies of effective materials and trained technicians. The process of using a mould to manufacture a bottle cap should be defect free and as low-cost as possible.

Plastic Bottle Cap Mould is traded by many countries in the world. The page features a comprehensive listing of Plastic Bottle Cap Mould suppliers based in India. The page also analyzes the potential of these Indian suppliers in the global market. Make sure to allocate a good supplier in your search. This will help you to find a reputable supplier with excellent quality and competitive pricing.

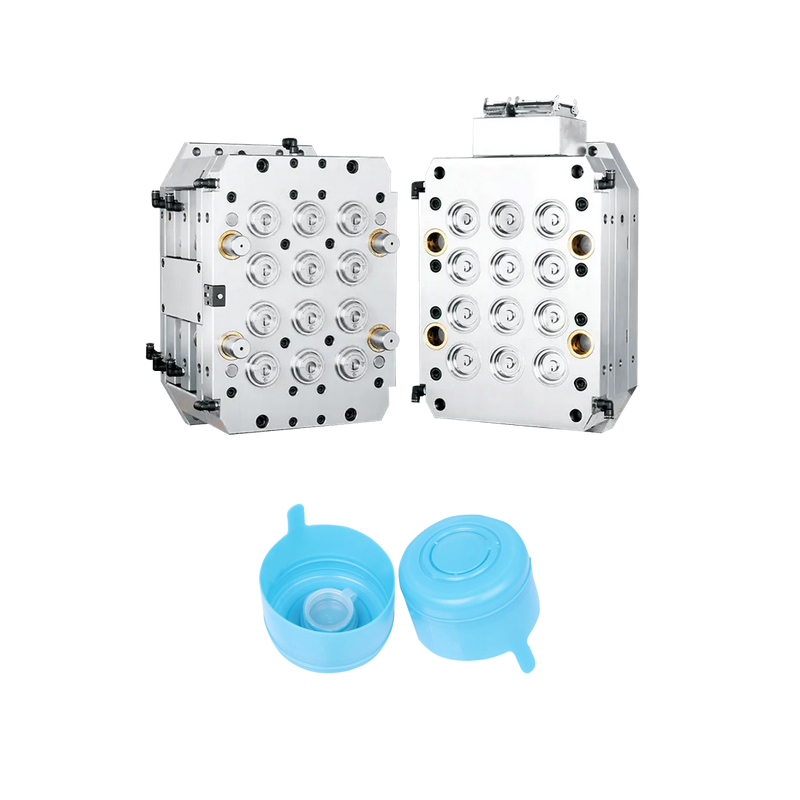

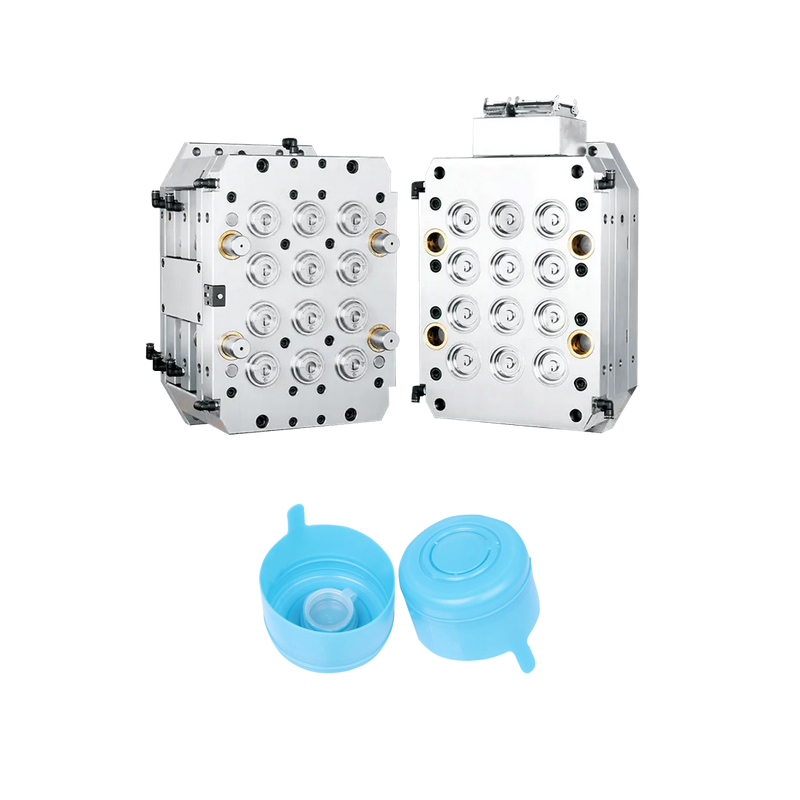

Multi cavity plastic injection bottle cap mould

Plastic 5 Gallon Bottle Cap Mould

Product Description:

1. Product Size: Suitable for 5 gallon bottle

2. Cap material: PP

3. Cap weight: 8.5g

4. Mould cavity: 12 Cavities

5. Mould core & cavity material: P20, 718, H13 etc. Mould base: 45# or LKM

6. Runner System: hot runner / Cold runner

7. Delivery Time: 35 - 50 days

Our factory is specialized in offering different kinds of plastic cap mould solutions for flip-top cap moulds, water cap moulds, cosmetic cap moulds, shampoo cap moulds and so on.

If you are looking for a one-stop solution for your new gallon cap mould project, contact us today!