Bottle Cap Mould

A Bottle Cap Mould is a tool that is used to make bottle caps in a variety of shapes, sizes and colors. The key to creating a successful product is to choose a bottle cap mould that is both robust and durable. In order to prevent damage, the cap mould should be covered and inspected periodically. When cleaning the cap mould, it is important to avoid abrasive materials and use a compatible cleaning solution.

There are two main types of Bottle Cap Moulds. The first type is called a pouring mould and the second one is called a bottle cap mould. Both types of moulds have their advantages. One type is easier to process and requires lower temperatures, while the other requires higher temperatures and extrusion pressure.

The temperature of the resin in the Bottle Cap Mould is important for the proper dimension. As the mould temperature rises, the volume and dimension of the cap are reduced. The temperature of the resin also affects the size of the die. For example, green closures are larger than orange ones. The proportion of weight to volume increases as the temperature decreases.

There are many uses for a Bottle Cap Mould. The most popular one is for sealing liquids in bottles. These types of closures can be used for foods, pharmaceuticals, and vitamins. A Bottle Cap Mould allows a manufacturer to create the bottle caps they need. The process is fast, simple and convenient.

Most Bottle Caps are made through a process known as injection moulding. In this process, thermoplastic polymer pellets are heated in a metal hopper to soften. They are then injected under high pressure into a complex steel mould. The cap is then ejected from the mould once it hardens.

Bottle Caps are also made using a lining material. This lining material protects the bottle from chemicals. The also acts as a seal, which helps keep the liquids inside the bottle. The wad can also help prevent tampering as it makes it more noticeable if someone tampered with the contents. This can be useful in protecting the public from ingestion of poisonous substances.

Bottle Caps can be made of different materials, including glass, aluminum and plastic. Depending on the use of the product, bottle caps need to be made from the right material. Bottle caps made from plastic should be food grade polymers. Aluminum caps should be grouped together, while steel caps should be grouped together.

Embossed bottle caps can be attractive to customers and users. The embossing can be combined with custom colours and can last long after labels are removed. Some manufacturers include this option in the bottle cap manufacturing process at no additional cost.

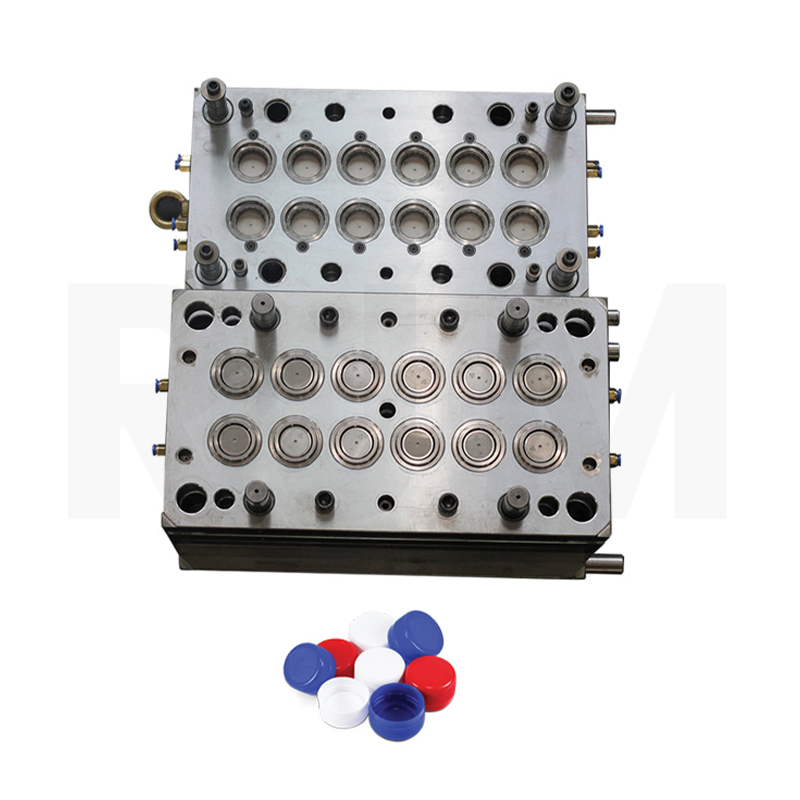

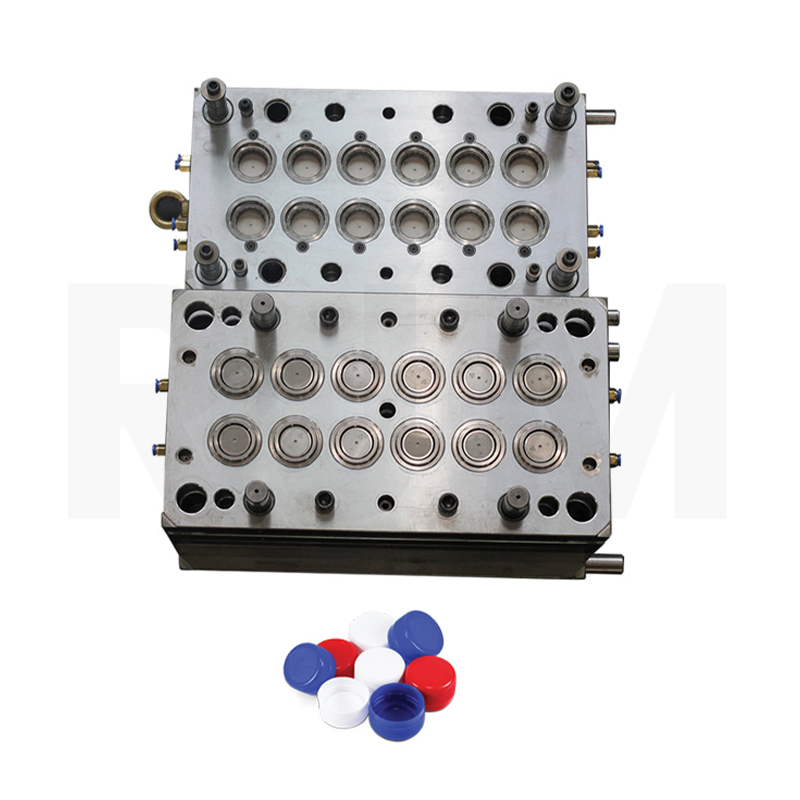

Multi cavity plastic injection bottle cap mould

Multi cavity plastic injection bottle cap mould

12-cavity Water Bottle Cap Injection Mould

Product Description: 2g caps for water packaging industry

1. Product Size: PCO28mm

2. Mould Cavity: 12 Cavities

3. Mould Main Material: S136 stainless steel with HRC48-50

4. Runner System: hot runner

5. Delivery Time: 35 - 50 days

-

|

Mould material

|

45# 50# 718 2738 P20 H13 S136 etc

|

|

Cavity Number:

|

As per customer

|

|

Runner System:

|

Hot runner / Cold runner

|

|

Hot runner Brand:

|

Local brand or YUDO

|

|

Mould Design:

|

3D Model/2D drawing

|

|

Design Time:

|

Within 1 week

|

|

Mold Life:

|

0.5 to 1 million shots guarantee, depends on your needs

|

|

Delivery Time:

|

30 to 70 days as per design

|

English

English Español

Español

pmj01.png)

pmj03.png)