A chair mould is a cavity in aluminium or stainless steel that is used to produce a chair. It can be a single or multi-part mould, depending on the process. When a mould is in place, it clamps together so that plastic can flow into it and then open again to release the part. A mould is used to produce chairs from almost any material. The material used depends on the design and its properties.

The process of manufacturing a mould involves plastic pellets which are introduced into a special injection device. These plastic pellets are allowed to flow back into the mould, where they take on the shape of the chair that is being produced. This process is ideal for short-run productions, since the moulds are generally designed to have uniform wall thicknesses.

When installing a mould, you must take the time to decide on the type of material used for the moulding. You should choose a material that will match the surrounding decor, including paint or wallpaper. Once you have selected the material, it is time to determine how the chair mould will fit into the area. Some moulds are more suitable for indoors than others.

In the case of a plastic chair mould, the sizing material is typically 20-30% of the overall volume. To achieve this, a nitrogen pump is used to marginally inflate the chair leg chamber. While the plastic sizing material may not fill the entire leg chamber, it can fill the second groove 41.

Chair moulding is one of the most common types of moulding. It is a horizontal strip of moulding that forms the chair rail. A chair rail is a popular design element and serves both a functional and aesthetic purpose. If you're looking for a way to add a decorative accent to a wall, chair rail moulding can be the perfect choice.

There are a variety of styles and materials that make for a beautiful chair mould. Choosing the right style will depend on your style and the style of your wall. Traditional chair rails are often painted or stained to match the baseboards, but some modern designers like to paint chair rails to match the wall color.

The moulding process takes several steps. First, the plastic materials that are used are melted. This allows them to cool down uniformly and avoid deformities. Once the molding process is complete, the part is removed from the mold. It can be cleaned with hot water and an ammonia-based cleaning solution. Afterward, use a sponge to clean the surface of the mould.

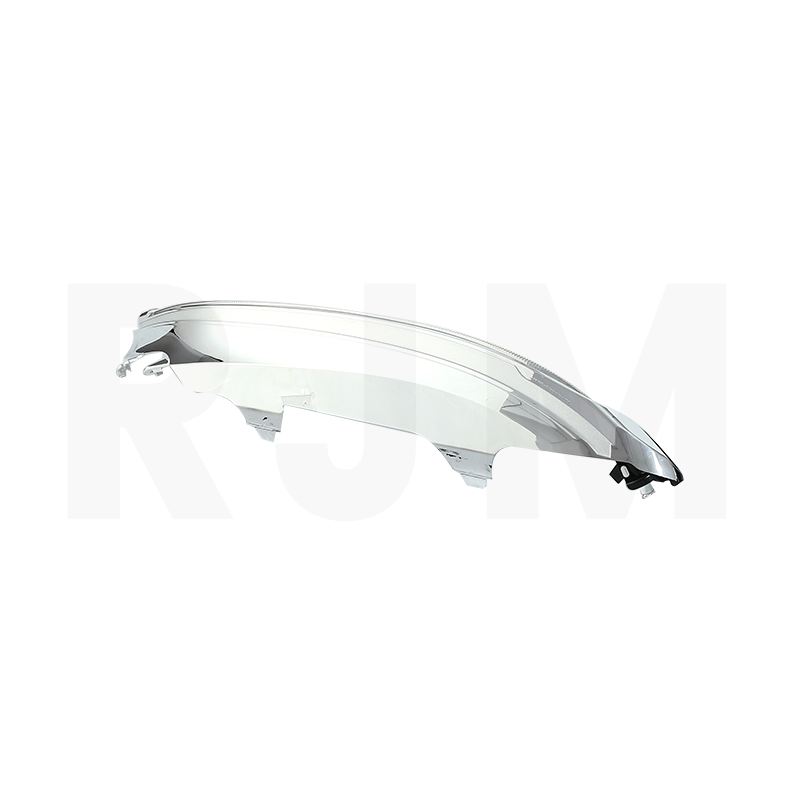

Outdoor plastic rattan chair mould

Outdoor plastic rattan chair mould

-

|

Mould material

|

45# 50# 718 2738 P20 H13 S136 etc

|

|

Cavity Number:

|

As per customer

|

|

Runner System:

|

Hot runner / Cold runner

|

|

Hot runner Brand:

|

Local brand or YUDO

|

|

Mould Design:

|

3D Model/2D drawing

|

|

Design Time:

|

Within 1 week

|

|

Mold Life:

|

0.5 to 1 million shots guarantee, depends on your needs

|

|

Delivery Time:

|

30 to 70 days as per design

|

English

English Español

Español

pmj01.png)

pmj04.png)